CJC Industry Solutions

Aluminum ExtrusionAluminium is widely used for many different applications. Aluminium is completely recyclable and the production of aluminium products are often a combination of ‘old’ aluminium and new aluminium. One of the common ways to use aluminium is by using aluminium profiles. Aluminium profiles are made by extrusion and are very versatile, where many different profiles can be made, just by using a different die tool for the extrusion process.

| |||

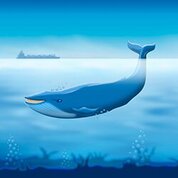

Blue Baleen Oil Absorption SystemThe CJC™ Blue Baleen system helps to ensure compliance with the environmental regulations and safe-guards against oil spillage with bilge water over board.

| |||

CementCement plants are complex production plants in rough environments, and reliable equipment is the key to maintaining a high output. Due to the high temperature and high amount of dust in the environment, it is critical to remove all oxidation residues and to keep the oil clean and dry.

| |||||||

Crusher Oil FiltrationCrushers operate under extreme environmental conditions, where high ingress of dirt is seen on a regular basis and in some cases water. This leads to highly contaminated systems and dirty oil with critically high dirt and water content, which can have a crucial impact on the system components and reliability.

| |||

Marine Engine Lube Oil MaintenanceBy integrating a frequency converter into a PLC control, we can eliminate the need for any heating. This can potentially generate large savings, especially on large sump reservoirs/cross head engines.

| |||

Marine SolutionsFiltration and conditioning of diesel fuel is self evident. However, oil care on on-board hydraulic and lubrication systems is equally important. Continuous oil care prolongs the service life considerably on all types of on-board oil systems: Hatch covers, cranes, winches, ramps, thrusters, stabilizers, and steering gears.

| |||

Mining Filtration SolutionsThe main cause is wear induced by contamination through solid particles, water and oil degradation products. Oil degradation products - “soft contaminants” - are precursors to the sticky varnish that deposits on metal surfaces. It is a common perception that in-line oil filtration is sufficient. However it is the smaller particles - below 10 micron - which do most harm to a system.

| |||

Oil Filtration for Injection MouldingStoring diesel and biodiesel over time, decreases the oil quality in the tank. Contaminated diesel containing water, microbes and particles can cause damage to fuel pumps and injectors, resulting in breakdowns of the backup system.

| |||

Paper Industry SolutionsThe paper making process is a multistage process of harvesting, wood chip and pulp manufacturing, and paper making that are exposed to a variety of conditions. There are hundreds of oil systems, which most can benefit from getting a CJCTM filter fitted.

The two latter stages consist of a Pulp Mill and Paper Mill are the two most ideal candidates for CJC filters. The Mills utilize mass production and all downtime is very expensive. It is therefore recommended to utilize CJCTM filters to drastically reduce all oil‐related downtime. It is estimated that 80% of all problems and water in oil systems are caused by contamination of particles and fitting a CJCTM filter can remove about 40% of all downtime. (Rough estimates).

| |||

Power Filtration SolutionsThe test results show that the filter does an excellent job in cleaning the oil. The test also proved that when oxidation residues are present, it is necessary to use oil sampling and trend analyses to predict CJC™ Filter Insert change. We provide solutions for traditional and renewable energy sources.

| |||

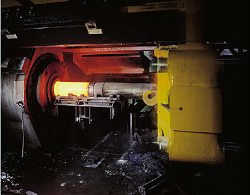

Steel Industry SolutionsSteel mills are often suffering from large contamination and water problems. The production of steel generates many particles which end up in the oil. The metal particles does much damage to both the oil and the machinery.

Steel mills often use high viscosity oils, where it can be hard to separate water from oil. Due to high operating temperatures in the production heat related problems, shown as vanish and sludge and condensed water in the oil will most probably occur.

| |||

Transfer Oil MaintenanceIn production where high processing temperatures are necessary (140-310oC) there is an option of using special types of oil, heat transfer oil, as heating medium instead of water and steam. Oil has the advance that is does not boil at these temperatures, giving less restrictions to the overall system compared to a water/steam system.

The process itself can be many different things and heat transfer oil systems are found in various industries with very diverse productions, including: food processing industry, petrochemical industry, steam production, rubber and plastic industry, oil industry, paper industry, ferry boats, and many more!

| |||

Quench Oil SolutionsQuenching is used to change steel properties by means of cooling. By heat treatment it is possible to influence the hardness, deformability and energy absorption by fracture of the material.

Quench oil serves two primary functions. It facilitates hardening of steel by controlling heat transfer during quenching, and it enhances wetting of steel during quenching to minimize the formation of undesirable thermal and transformational gradients which may lead to increased distortion and cracking.

| |||

Wind Sector SolutionsSolutions for removal of particles, water and oil degradation products from hydraulic oil and lube oil from wind turbines.

| |||